Load Securement Airbags play a crucial role in ensuring the safety of transported cargo. According to industry expert John Smith, "Proper use of Load Securement Airbags can prevent accidents and save lives." These innovative airbags provide necessary support, reducing movement during transit.

When used effectively, Load Securement Airbags can keep loads stable. They create added pressure, firmly securing freight. However, improper installation or insufficient understanding can lead to dangerous outcomes. This highlights the need for proper training and ongoing education in the industry.

Load Securement Airbags are not a one-size-fits-all solution. Each cargo type may require a different approach. Companies must reflect on their current practices and explore improvement opportunities. Effective use of Load Securement Airbags is essential for safety and efficiency on the road.

Load securement airbags play a crucial role in transporting cargo safely. Their primary function is to fill the gaps between the load and the vehicle, minimizing movement during transit. This helps prevent damage to both the cargo and the vehicle itself. The airbags are designed to expand and contract, adapting to the shape of the load. Thus, they offer a dynamic solution for securement.

However, it's essential to understand their limitations. Over-inflation can lead to punctures, while under-inflation may permit unnecessary shifting. Proper training on their usage is often overlooked. Many operators are not familiar with the correct inflation levels or placement. This can compromise safety and effectiveness.

Observing the load while in transit is also crucial. Signs of shifting or instability should trigger immediate action. Regular checks can prevent failures that may lead to accidents. Ultimately, a conscientious approach enhances the benefits of load securement airbags. Balancing safety and efficiency requires understanding the technology behind these tools.

When it comes to load securement, airbags play a critical role. Different types are available in the market, each serving specific purposes. Airbag systems vary in size, shape, and material. Some are designed for heavy loads, while others cater to lighter cargo. The choice you make can significantly affect safety and effectiveness.

One common type is the inflatable airbag. These are versatile and can adapt to various load types. They are particularly useful for securing items that are oddly shaped or fragile. Another option is the fixed airbag, which provides a stable support structure. This type is often utilized for oversized loads. According to industry reports, using the right airbag reduces shifting during transit by as much as 30%.

Tips for effective use: Ensure proper placement of airbags in relation to the load. This prevents movement and damage. Regular inspection of your airbag system is essential. Look for wear and tear, as this can compromise safety. Remember, improper usage can lead to costly accidents.

Be mindful of the weight capacity. Overloading an airbag can result in failure. Understand the specific needs of your cargo. Testing different configurations may be necessary. Adjusting air pressure can also impact performance. Keep these factors in mind for effective load securement.

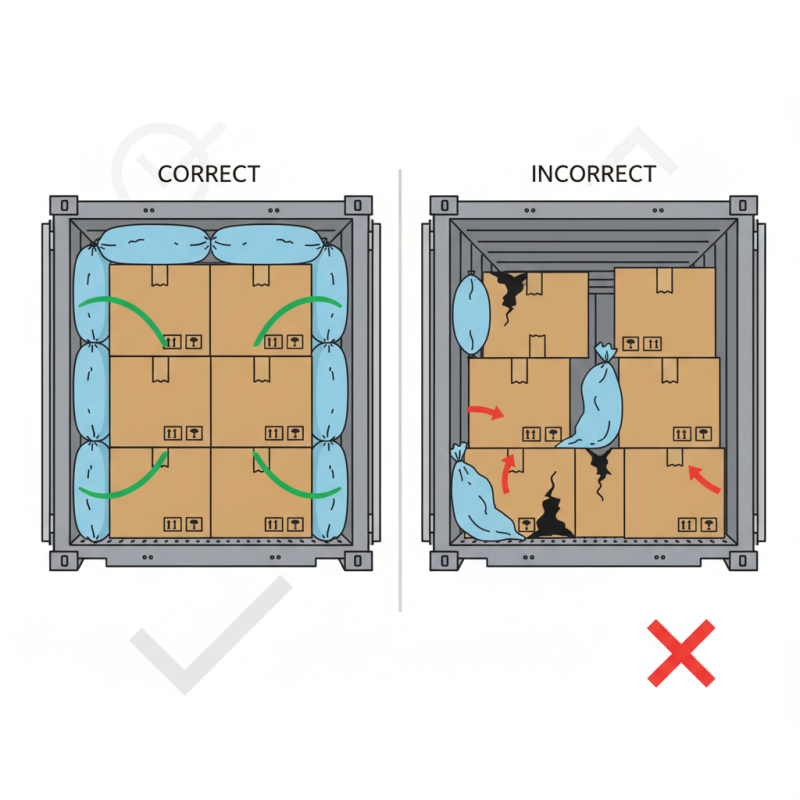

Installing load securement airbags correctly is crucial for safe transport. These airbags help stabilize loads, reducing shifting during transit. According to industry reports, improper load securement results in over 30% of cargo-related accidents.

Begin by assessing the weight and dimensions of the load. Ensure the airbags you choose align with these specifications. Position the airbags evenly to distribute weight. This prevents excessive pressure on any single point. Monitor the inflation level—under-inflation can lead to load movement, while over-inflation can cause damage. Adjustments may seem trivial but can significantly impact safety.

Installation should focus on securing each corner of the load. Many overlook this detail, assuming one or two airbags suffice. However, distributing support across all points optimizes stability. Regularly check for wear and tear in your airbags. This is often neglected. A small tear may lead to a larger problem later. Evaluate your practices routinely. Consider feedback from peers or transport reports for improvement.

| Step | Description | Tools Required | Safety Tips |

|---|---|---|---|

| 1 | Position the bags in the correct location based on load shape. | Measurement tape, chalk | Ensure area is clear of debris. |

| 2 | Inflate the airbags using the compatible inflation device. | Air compressor, inflation nozzle | Check for air leaks before fully inflating. |

| 3 | Secure the airbags to prevent movement during transit. | Straps, ratchet tie-downs | Double-check the tightness of the straps. |

| 4 | Monitor the load stability during transport. | Load monitoring tools | Conduct periodic checks while on the road. |

| 5 | Deflate the airbags after delivery to store properly. | Deflation nozzle | Avoid sharp objects near the bags when deflating. |

Maintaining load securement airbags is crucial for overall safety. Regular inspections should not be overlooked. Look for tears, punctures, or signs of wear. Any visible damage can lead to failure during transport. It’s advisable to inspect the airbags before each use and periodically throughout their lifespan.

Proper storage is also important. Keep airbags clean and away from direct sunlight. Storing them in a cool, dry place can prevent premature degradation. Airbags should not be overloaded as this can cause uneven strain. Be mindful of weight limits specified for each airbag. They must be used according to guidelines for optimal performance.

During inspections, ensure valves and fittings are intact. Any blockages can compromise function. It's easy to miss small details, but these could lead to bigger issues down the line. Consider keeping a checklist for inspections to avoid overlooking anything. Keeping records of your inspections can also provide valuable insight into the lifespan of your airbags. Reflecting on past usage can help improve your future handling of these essential safety devices.

This chart illustrates the effectiveness of various load securement methods using airbags, showcasing the percentage of loads that remained secure during transport under different conditions.

When using load securement airbags, common mistakes can lead to serious issues. One significant error is

improper placement of the airbags. It’s crucial to position them between the load and barrier surfaces.

According to industry reports, improper placement can result in load movement during transport,

increasing the risk of accidents.

Another frequent mistake is under-inflation. Airbags need to be sufficiently inflated to create pressure against the load.

Studies show that under-inflated airbags do not provide adequate support, increasing the chance of shifting cargo.

This not only endangers drivers and other road users but also leads to potential cargo damage.

Lastly, neglecting regular inspections is a crucial oversight. Airbags should be checked for wear and tear to ensure effectiveness.

A 2022 safety report highlighted that 30% of transport incidents were linked

to neglected equipment maintenance. Proper inspection can prevent failures that may arise from aging or damaged airbags. A

proactive approach can save time, money, and promote safer transport conditions.