When embarking on a project that requires the use of materials, selecting the right one is crucial for ensuring durability and effectiveness. High-Density Polyethylene (HDPE) sheets have gained popularity across various industries due to their exceptional resistance to impact, chemicals, and UV radiation. According to a report by Allied Market Research, the global HDPE market was valued at approximately $62 billion in 2020, with a projected growth rate of 5.3% from 2021 to 2028. This upward trend underscores the increasing reliance on HDPE sheets in applications ranging from construction and agriculture to packaging and manufacturing. Given these insights, it's essential to carefully consider the specific requirements of your project when choosing the appropriate HDPE sheet, ensuring alignment with performance expectations and environmental conditions.

When selecting the right HDPE (High-Density Polyethylene) sheet for your project, it’s crucial to understand the different types available. HDPE sheets come in various grades, each designed for specific applications. For instance, general-purpose HDPE sheets are suitable for standard applications, while UV-resistant sheets are essential for outdoor use, where exposure to sunlight could degrade the material over time. Additionally, food-grade HDPE sheets are engineered to meet safety standards for use in food processing and handling, ensuring that they do not contaminate food products.

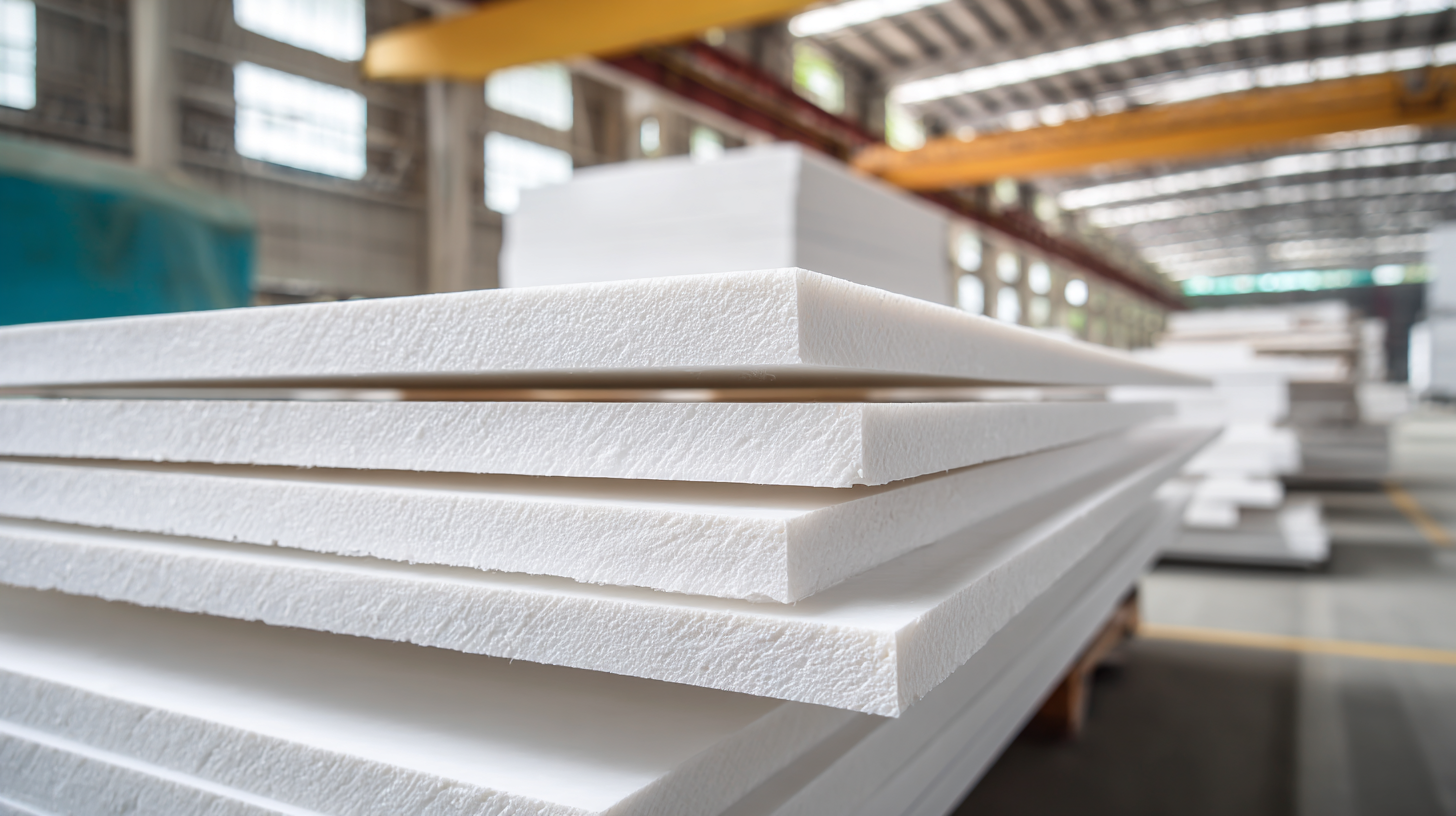

Beyond the grades, HDPE sheets can be differentiated by their thickness and texture. Thicker sheets offer added durability and resistance to impact, making them ideal for heavy-duty applications. Conversely, thinner sheets may suffice for lightweight uses, such as packaging or temporary structures. Surface textures can also play a role in functionality; textured sheets provide better grip and slip resistance, which is beneficial in flooring applications. By understanding these distinctions, you can make an informed choice that aligns with your project requirements.

When it comes to selecting the right HDPE sheet for your project, evaluating the thickness and strength requirements is crucial. The thickness of the sheet determines its durability and ability to withstand various stress factors. For instance, if your project involves heavy loads or high-impact conditions, opting for a thicker sheet will provide the necessary strength to resist deformation. Generally, sheets ranging from 0.5 inches to 1 inch are suitable for industrial applications, while thinner sheets may suffice for lighter household projects.

When selecting the right HDPE sheet for outdoor applications, it is crucial to consider environmental factors. With an impressive projected growth in the outdoor gear and equipment market, expected to expand from $568.25 billion in 2024 to $943.87 billion by 2033 at a CAGR of 5.8%, the demand for durable materials like HDPE is rising. The resilience of HDPE sheets against harsh weather conditions, UV radiation, and extreme temperatures makes them a preferred choice for manufacturers targeting the outdoor sector.

Additionally, the global outdoor decor market is also on the rise, anticipated to grow from $9.283 billion in 2025 to $11.222 billion by 2033, with a CAGR of 2.4%. This growth emphasizes the importance of selecting materials that not only meet aesthetic expectations but also withstand environmental stresses over time. Companies must prioritize sourcing HDPE sheets that are both environmentally friendly and sustainable to align with consumer demands for responsible outdoor products.

When selecting the right HDPE sheet for your project, understanding the balance between cost and quality is paramount. HDPE, known for its durability and versatility, comes in various grades and prices. Lower-cost options may seem attractive, but they can compromise quality, leading to potential issues down the line. Materials that don’t meet industry standards may not withstand environmental stressors, resulting in additional expenses for replacements or repairs.

Investing in high-quality HDPE sheets can save you money in the long run. While they may require a higher initial investment, these sheets typically offer better performance, longer lifespans, and enhanced resistance to wear and tear. Evaluating your project's specific needs—such as load-bearing requirements, exposure to chemicals, and environmental conditions—will help you make an informed choice. By prioritizing quality over initial cost, you ensure a reliable and efficient solution that meets your project's demands.

| Tip | Description | Cost Range (per sheet) | Quality Rating (1-10) | Applications |

|---|---|---|---|---|

| 1. Assess Project Requirements | Identify the specific needs of your project to choose the right thickness and density. | $10 - $30 | 7 | Signage, outdoor display |

| 2. Compare Suppliers | Research different suppliers to find competitive pricing and quality options. | $15 - $35 | 8 | Residential, commercial |

| 3. Evaluate Environmental Factors | Consider temperature extremes, UV exposure, and chemical agents. | $20 - $50 | 9 | Outdoor furniture, marine |

| 4. Review Certifications | Ensure the HDPE sheets meet industry standards for safety and performance. | $25 - $45 | 8 | Manufacturing, construction |

| 5. Analyze Weight and Durability | Choose material that offers longevity and is easy to transport. | $30 - $60 | 9 | Industrial, agricultural |

| 6. Seek Expert Guidance | Consult with experts for tailored recommendations based on your project. | $10 - $40 | 7 | Custom projects, prototypes |

| 7. Factor in Long-Term Costs | Consider maintenance and replacement costs over time. | $15 - $55 | 8 | Parks, recreational areas |

When selecting HDPE sheets for your project, it is crucial to identify reliable suppliers who adhere to established quality standards.

Quality control (QC) processes are integral in ensuring that the HDPE sheets manufactured meet the necessary specifications and performance criteria.

Businesses need to implement robust QC measures throughout the supply chain to track and manage product quality effectively, mitigating risks that can arise from inadequate oversight.

Additionally, fostering collaboration within the supply chain can enhance supplier relationships and increase resilience.

It is essential to engage with suppliers who not only comply with quality standards but also understand the significance of sustainable practices.

Evaluating supplier diversity is another key consideration, as it can create a more inclusive supply chain while ensuring compliance with legal requirements.

By pursuing a comprehensive approach to supplier identification and quality assurance, businesses can secure HDPE sheets that meet their project needs while promoting ethical and sustainable practices within their operations.