How to use the rachet tie down lashing straps correctly?

The main steps for using a ratchet tie down cargo lashing straps are as follows:

1 . Check the status of equipment and goods.

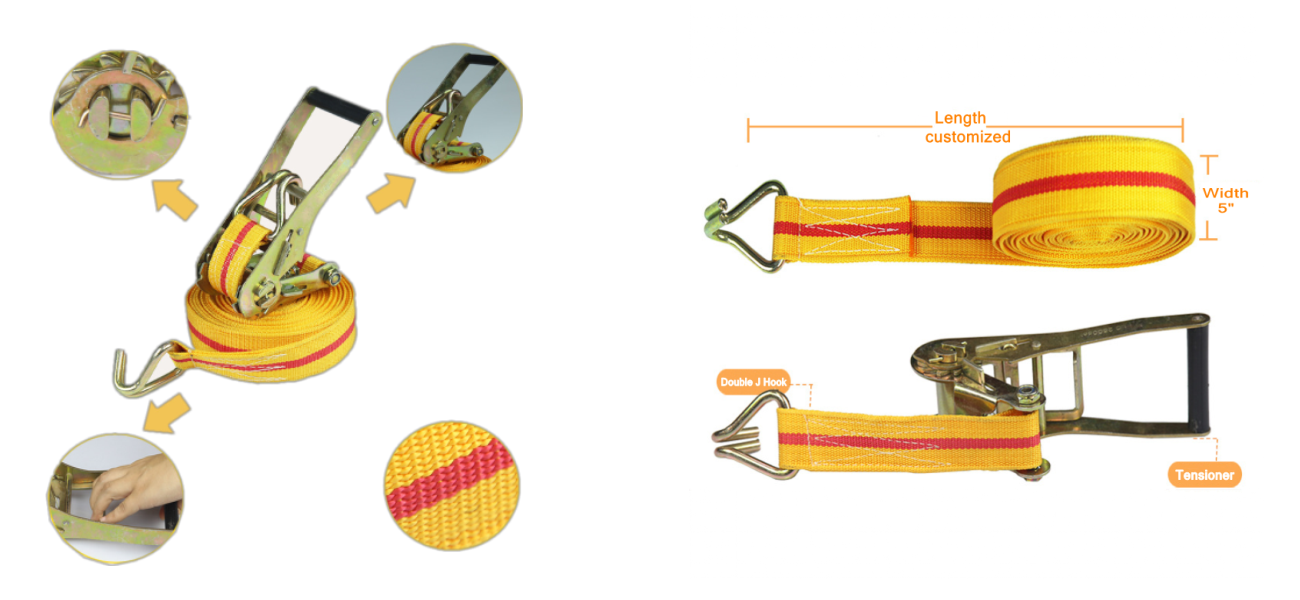

Confirm that all components of the ratchet tie down Lashing Strap (such as hooks, ratchet wheels, and webbing) are intact and undamaged, and that the webbing is not worn or broken.

Protect the sharp parts of the surface of the goods with Corner Protectors or rubber pads to avoid scratching the webbing or damaging the goods.

2. Connect the goods and preliminarily fix them.

Secure the hook of the ratchet tie down lashing strap to the anchor point of the cargo or transport vehicle (such as the base of a wooden crate or pallet, container door frame, etc.), ensuring that the hook is fully fastened and will not fall off.

Step the ribbon over the goods and adjust it to the appropriate position to avoid winding too tightly, which may cause deformation of the goods or breakage of the ribbon.

3. Tighten the operation.

Manual tensioner: By rotating the handle or swinging the handle, the webbing is wrapped around the ratchet shaft 4-5 times and tightened; If you need to tighten it more, you can repeat this action.

Automatic tensioning device: Some models can automatically adjust the tightness through a motor or manual tension sensor, and the appropriate range needs to be set according to the weight of the goods.

4. Locking and security checks.

After confirming that the ratchet is fully locked, gently shake the goods with your hand to test for stability; If looseness is found, it needs to be tightened again.

During transportation, it is necessary to regularly check the status of the ratchet tie down lashing strap (such as loose fabric, hook detachment, etc.) and re fix it if necessary.

Remarks:

1. Avoid excessive tension that may cause deformation of the goods or breakage of the webbing; Suggest selecting a suitable tonnage ratchet tie down lashing strap based on the weight of the goods.

2. Long term exposure to rainwater and oil pollution may accelerate aging, and it is recommended to store in a dry place.

3. When using specialized clamps or clips, ensure that their openings face downwards and are fully clamped.